Fluidose® Series 6

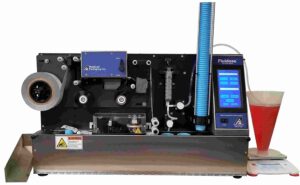

Fluidose® Series 6: Liquid Unit Dose Packaging Solution

The Fluidose® Series 6 Unit Dose Packaging System delivers automated liquid packaging solutions for hospitals, acute care facilities, extended care pharmacies, and specialty pharmaceutical manufacturers. This advanced packaging machine addresses the rising demand in the global liquid packaging market for efficient, compliant liquid cup product packaging and provides a reliable liquid packaging solution for healthcare facilities.

Key Benefits

- Automated Efficiency: Produces up to 22 doses per minute with integrated syringe pump mechanism

- Cost Savings: Significantly reduces costs compared to pre-packaged doses

- Enhanced Safety: Advanced barcoding and error prevention capabilities

- Regulatory Compliance: FDA-registered materials and Joint Commission compliance

- Flexible Operations: Supports both rigid liquid packaging and flexible liquid packaging requirements, giving facilities more packaging options.

Target Applications

- Hospitals and acute care facilities seeking flexible packaging solutions

- Extended care and long-term care pharmacies managing diverse patient populations

- Independent and retail pharmacies requiring cost-effective automation

- Specialty pharmaceutical manufacturers and CMDOs optimizing production lines with automated packaging machines designed for the pharmaceutical industry

- Pharmaceutical repackagers and dental pharmacies needing scalable packaging solutions

Automated Liquid Packaging Process

The Fluidose® Series 6 streamlines liquid packaging through intelligent automation designed for the pharmaceutical industry.

Core Technology

- Integrated Syringe Pump: Automates filling, sealing, and barcoding of liquid product doses

- 7″ Touchscreen Interface: Easy parameter control for volume, seal temperature, and pump speed

- Multi-layered Materials: Controlled sealing process ensures safe, tamper-proof packages

- Automatic Detection: Low-fluid monitoring prevents interruptions and ensures accuracy

Packaging Process Steps

- Setup: Configure dosing parameters via intuitive touchscreen interface

- Loading: System uses FDA-grade disposable tubing and latex-free syringes

- Filling: Precise syringe pump delivers consistent doses across various viscosities

- Sealing: Controlled temperature sealing creates secure, tamper-proof packages

- Labeling: Thermal transfer printing applies barcodes directly to Fluidose-LIDDING

- Verification: Optional barcode scanner ensures readability for bedside scanning

Optimal Compliance

Flexible Packaging Solutions

- Multiple Cup Sizes: 7ml, 15ml, 25ml, and 35ml options for diverse liquid product needs

- Color Coding: Blue, red, yellow, and amber cups for medication identification

- Custom Options: Additional colors available for specialized applications

- Tool-Free Changes: Switch between cup sizes without additional equipment

Advanced Compliance Features

- FDA-Registered Materials: Class A standards for moisture and light protection

- Joint Commission Compliance: Meets strict oral liquid medication dispensing regulations

- UL Compliance: Certified safety standards for healthcare environments

- Extended Shelf Life: One-year beyond-use date or original expiration, whichever is shorter

- Quality Control: Rigorous manufacturing standards throughout packaging process

Error Prevention Technology

- Advanced Barcoding: Linear, 2D, and GS1 format compatibility

- Tall-Man Lettering: Distinguishes look-alike/sound-alike medications

- Bulk Container Scanning: Additional verification layer before packaging

- Barcode Verification: Optional scanner ensures readability at point of care

User-Friendly Design

- Intuitive Controls: 7″ color touchscreen with customizable settings

- Automated Monitoring: Low-fluid detection with automatic pause functionality

- Minimal Downtime: Quick setup changes and efficient operation

- Safety Features: Protective guard and interlock switch for operator protection

Address Critical Liquid Packaging Market Challenges

Eliminate Manual Packaging Inefficiencies

- Automated Packaging Process: Reduces labor costs and human error

- Consistent Output: Up to 22 doses per minute with reliable accuracy

- Streamlined Workflow: Integrates seamlessly into existing production lines

- Scalable Solution: Handles both low and high-volume packaging needs

Overcome Compliance Burdens

- Regulatory Ready: FDA-registered materials meet pharmaceutical standards

- Documentation Support: Comprehensive quality control and traceability

- Audit Trail: Complete packaging process documentation for compliance reviews

- Standards Adherence: Joint Commission and UL compliance certifications

Reduce Labeling Errors

- Automated Printing: Direct barcode application eliminates manual labeling

- Verification Systems: Multiple checking layers prevent medication mix-ups

- Clear Identification: Color-coded cups and professional labeling

- Integration Ready: Compatible with existing pharmacy management systems

Competitive Advantages in Global Market

Cost-Effective Automation

- Low Cost Per Dose: Economical alternative to pre-packaged medications

- Reduced Storage Space: Eliminate bulk pre-packaged inventory requirements

- Operational Efficiency: Minimize staffing needs while maintaining quality

- ROI Optimization: Quick payback through reduced packaging costs

Innovative Approach to Liquid Packaging

- Advanced Technology: Proprietary thermal transfer printing system

- Quality Barrier Protection: Multi-layer materials ensure medication integrity

- Flexible Liquid Packaging: Adaptable to diverse medication requirements

- Future-Ready Design: Supports evolving pharmaceutical packaging standards

Market Leadership Benefits

- Proven Technology: Trusted by healthcare facilities worldwide

- Durable Packaging: Long-lasting materials reduce replacement costs

- Expert Support: Comprehensive training and technical assistance

- Continuous Innovation: Ongoing development addresses environmental concerns

Technical Specifications

Performance Capabilities

- Speed: Up to 22 doses per minute (varies by liquid product viscosity)

- Cup Sizes: 7ml, 15ml, 25ml, 35ml flexible packaging options

- Barcode Support: Linear, 2D, GS1 compatibility

- Materials: FDA-grade disposable tubing, HDPE cups, high-barrier lidding—ensuring compliance with the liquid packaging process and supporting longer shelf life.

System Requirements

- Dimensions: 32″ L × 14″ W × 18″ H

- Weight: 105 lbs

- Power: 115VAC or 230VAC, 50/60Hz, 400VA

- Storage Space: 4′-5′ counter length minimum, 24″ depth

- Safety: CE, NRTL (MET) US, C Marks certification

Software Integration

- Pak-EDGE® Software: Included barcode labeling system

- Database Access: Optional First Databank integration

- System Compatibility: Windows 10+, network printer support

- Hardware Requirements: 8GB RAM, 10GB storage, USB ports

Complete Solution Package

Included Components

- Packaging System: Full Fluidose® Series 6 equipment

- Software License: Pak-EDGE® UD Barcode Labeling Software

- Training Materials: Comprehensive operator documentation

- Warranty: One-year limited warranty with extended options available

Optional Enhancements

- Barcode Verifier: Automated quality control scanning

- 2D Scanner: Bulk container verification capability

- Extended Warranty: Additional coverage and maintenance agreements

- Custom Colors: Specialized cup colors for unique applications

Frequently Asked Questions

Q: How much can our facility save with automated liquid packaging solutions compared to pre-packaged doses?

A: Healthcare facilities can achieve substantial cost reduction per dose compared to purchasing pre-packaged liquid products. The low cost per dose (CPD) of the Fluidose® Series 6, combined with eliminated vendor markups and reduced storage space requirements, delivers significant annual savings. Many facilities experience rapid return on investment based on their liquid packaging volume and operational efficiency gains.

Q: Will this system integrate with our existing pharmacy management software?

A: Yes, the Fluidose® Series 6 seamlessly integrates with most pharmacy management systems through the included Pak-EDGE® UD Barcode Labeling Software. The system supports linear, 2D, and GS1 barcoding standards used by major healthcare software platforms. Optional First Databank integration provides comprehensive drug data access for enhanced workflow efficiency in your packaging process.

Q: How does this help reduce medication errors in our busy hospital pharmacy?

A: The system includes multiple error prevention layers: automated barcode scanning of bulk containers before liquid packaging, Tall-Man lettering support to distinguish look-alike medications, and optional barcode verification to ensure bedside scanning accuracy. Color-coded cups (blue, red, yellow, amber) provide visual medication identification, while the automated packaging process eliminates manual labeling errors common in high-volume environments.

Q: What regulatory compliance does this system meet for our long-term care facility?

A: The Fluidose® Series 6 meets all major healthcare regulations including FDA registration for pharmaceutical industry materials, Joint Commission compliance for oral liquid medication dispensing, and UL safety standards. MPI-certified consumables provide Class A moisture and light protection with one-year beyond-use dating. The system supports complete audit trails required for regulatory inspections and durable packaging integrity.

Q: Can this handle our varying volume needs from 50 to 500 doses per day?

A: Absolutely. The flexible packaging solutions of the Fluidose® Series 6 accommodate both low and high-volume operations with production speeds up to 22 doses per minute. Four cup sizes (7ml, 15ml, 25ml, 35ml) handle diverse medication volumes, while tool-free size changes enable quick adaptation to daily volume fluctuations. The system efficiently serves specialty pharmacies with low daily volumes and busy hospital pharmacies with high-volume requirements.

The Fluidose® Series 6 represents the future of liquid packaging solutions in healthcare, delivering the automation, compliance, and efficiency required to succeed in today’s competitive pharmaceutical industry. Contact MPI today to transform your facility’s liquid packaging operations.

Contact MPI Today for Personal Assistance

If you would like more information about our company, our medication packaging and labeling machines and MPI-certified consumable materials, and the custom solutions we provide, click below to contact us today.